How Cooling Towers Reduce Operational Costs in Industries

Cooling towers play a pivotal role in enhancing industrial efficiencies, yet they often go unnoticed. By managing heat transfer more effectively, these systems not only preserve the integrity of machinery but significantly cut operational costs. Let's explore how cooling towers contribute to economical operations and sustainable practices in industrial settings.

The Efficiency Game: Cooling Towers at Work

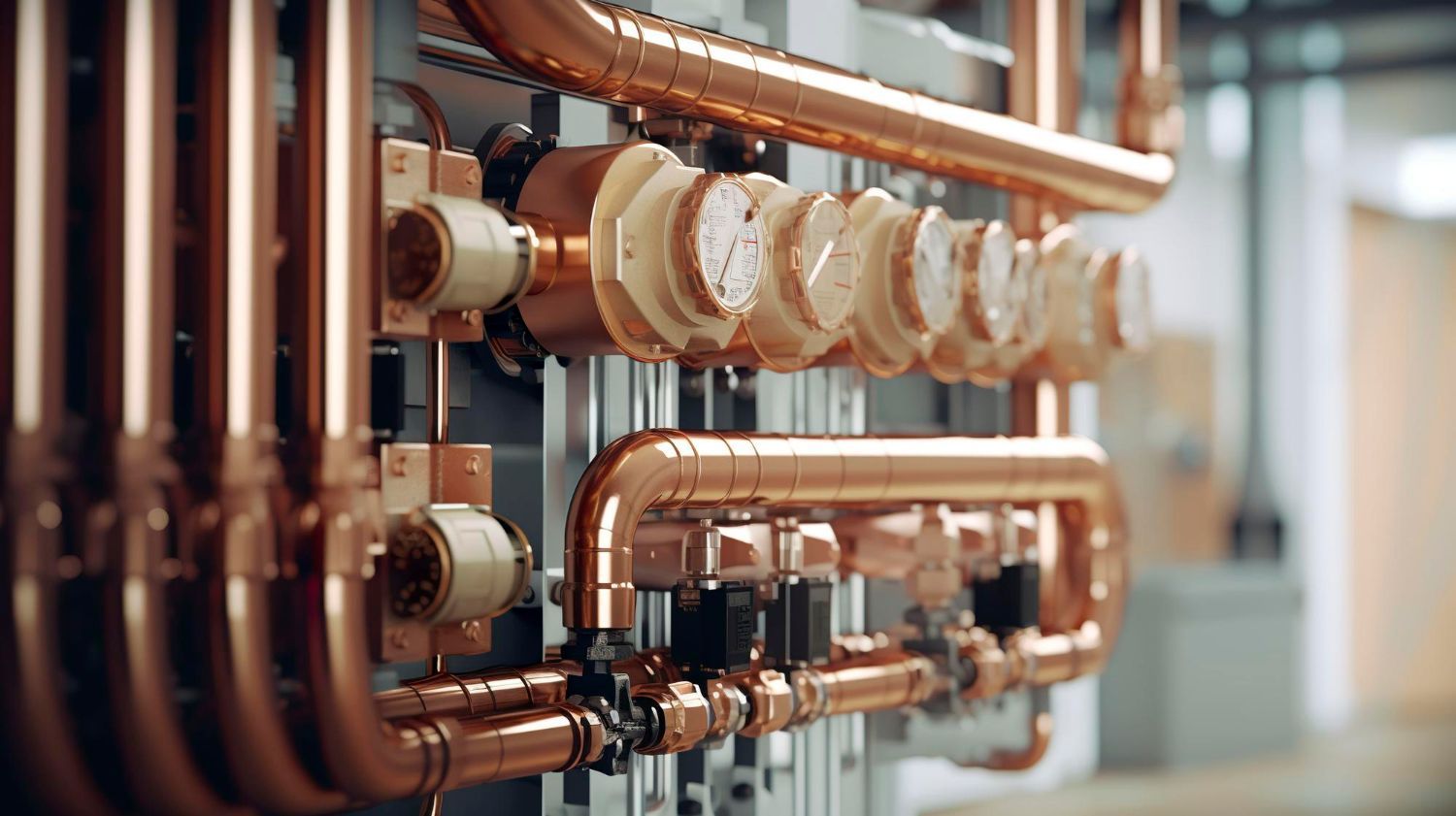

Cooling towers are essential for dissipating excess heat generated during various industrial processes. By maintaining optimal temperatures, they ensure that equipment functions smoothly. This efficiency reduces the energy required to cool machinery, directly translating to lower utility bills. The integration of advanced temperature and flow monitoring systems further heightens their efficacy. These systems precisely control cooling processes, minimizing energy waste and enhancing performance consistency.

Predictive Maintenance: A Cost-Saving Strategy

One of the standout benefits of modern cooling towers is their potential for predictive maintenance. Through the use of cutting-edge sensor technology, these towers can forecast potential issues before they escalate. Predictive maintenance circumvents unexpected failures, saving industries from costly repairs and operational halts. By investing in regular check-ups and monitoring, companies can extend the lifespan of their equipment, ensuring long-term savings.

Environmental Impact and Resource Conservation

Cooling towers aren't just about reducing costs; they're an ally in environmental sustainability. Many modern systems incorporate water recycling features, drastically cutting down on water usage. This not only lowers overall consumption but aligns operations with stringent environmental regulations. By reducing their ecological footprint, industries can enhance their reputation and meet sustainability goals without breaking the bank.

Advanced Control Systems: Precision and Savings

Incorporating sophisticated control systems, cooling towers allow industries to fine-tune their operations. These automated systems streamline processes, reducing manual oversight and enhancing efficiency. Consequently, companies experience fewer operational hiccups and more streamlined production cycles. The precision offered by these controls ensures consistent performance, which is vital for maintaining high-quality output and customer satisfaction.

Industries Benefiting from Cooling Towers

Cooling towers are indispensable in sectors where heat-intensive processes dominate, such as chemical manufacturing, power generation, and steel production. By efficiently managing thermal loads, they've become a critical component in these industries. The benefits are clear: reduced energy costs, enhanced equipment longevity, and adherence to environmental standards.

Embracing Sustainable Practices

In a world increasingly focused on sustainability, cooling towers offer a viable solution to industries aiming to reduce their carbon footprint. The incorporation of water recycling and energy-saving measures speaks to a broader commitment to eco-friendly operations. This alignment not only benefits the planet but significantly improves an organization's bottom line.

Unlocking the Potential of Cooling Towers

Understanding the multifaceted advantages of cooling towers reveals their integral role in cost reduction and sustainability. By optimizing energy use, predicting maintenance needs, and conserving resources, these towers pave the way for more efficient industrial operations. For businesses eager to harness these benefits, collaboration with a specialized provider is crucial.

Reach out to Atomic Plumbing and Mechanical for expert guidance tailored to your specific industrial requirements. Their advanced cooling tower services can transform operational efficiency while supporting your sustainability efforts. Contact them today to explore how you can make your operations more economical and eco-friendly.